What’s new in… Grain Harvesting Equipment: Harrington Seed Destructor

Originally published in Australian AgContractor Magazine November/December 2021 Edition

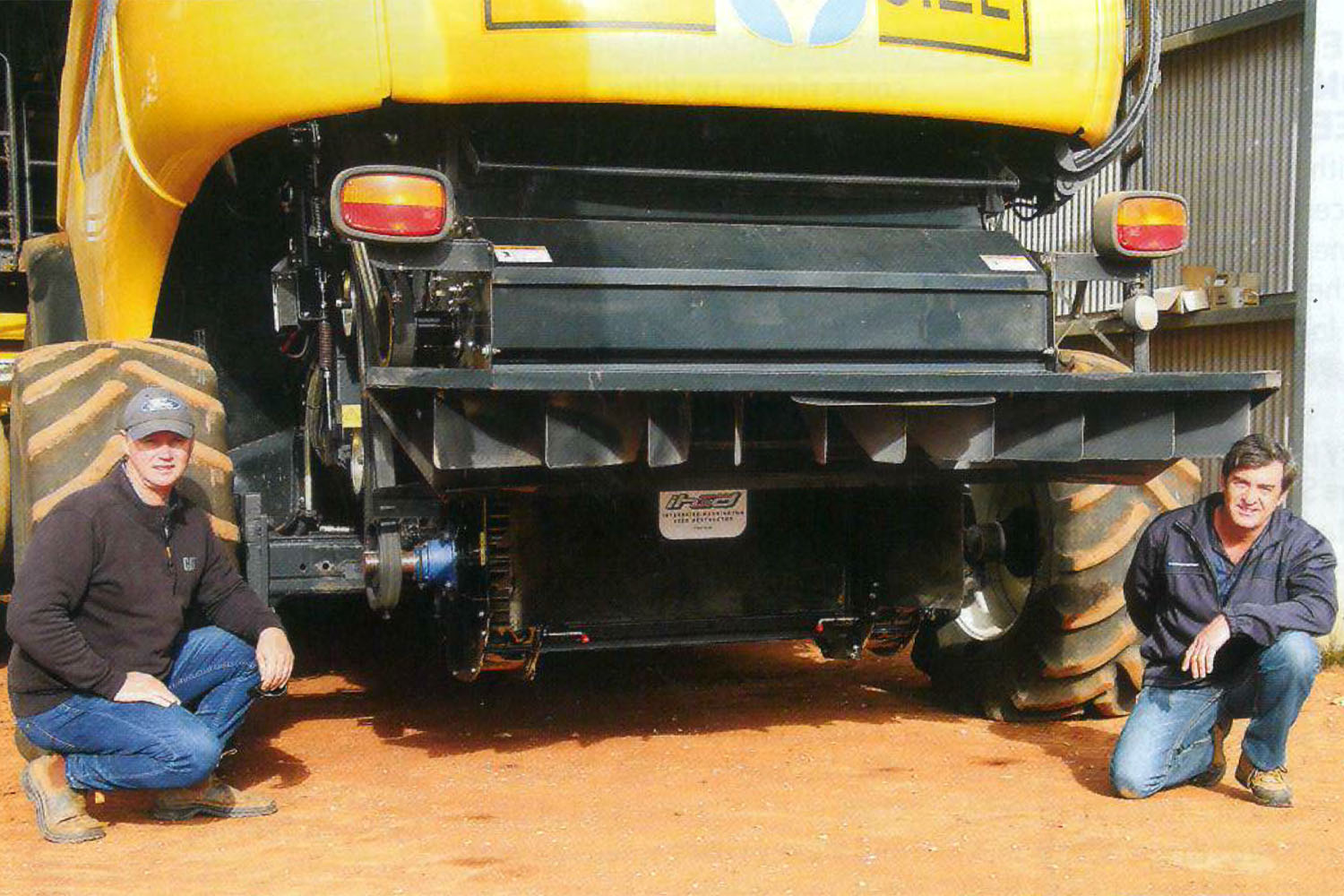

Riverina farmer Andrew Alexander has seen the benefits of mechanical weed seed control.

The Alexanders run New Holland CR9070 and CR9080 headers on their 4000-hectare cropping program on their property at Boree Creek in southern New South Wales. They fitted the new vertical, mechanical Harrington Seed Destructor to the more powerful CR9080 prior to harvest last year.

The Seed Destructor is shown to kill up to 99 percent of weed seeds in independent testing.

Andrew predominantly used it in the outer areas of paddocks near fence lines and firebreaks, which have been the primary problem areas for herbicide-resistant weeds.

After viewing the weed populations on the property, he says having one header with the Destructor and one without proved interesting.

“In some paddocks where the destructor had been there were virtually no weeds on the outside. There were some weeds in other areas where it had been used, but we suspected some of that came from hard seed two years ago,” Andrew says.

“When we had summer rain, it was noticeable that paddocks were a lot greener, including with volunteers, where the Destructor had not been used. The Destructor areas were a lot cleaner.”

This also resulted in reduced summer spraying for the Alexanders. They hope to be even better off in coming years, once hard weed seed areas diminish.

Andrew is the fourth generation of the Alexanders on the farm. He farms with his wife, Jacqui, and sons, Rory and Samuel.

Currently, they grow canola, wheat and barley over the property’s red loams, gravelly rises, and black soil plains.

Annual ryegrass has become the main problem weed in their continuous cropping rotation. They have seen resistance to some Group B and A herbicides, and resistance to glyphosate, particularly along fence lines.

Andrew says Trifluralin is still effective, and now they use a prickle chain behind the disc seeder to incorporate the herbicide.

Prior to investing in the Harrington Seed Destructor, the family did narrow windrow burning, but the did not enjoy it.

“It is a shocking job. It is very time consuming, and it is a fire danger,” Andrew says. “When we did it, however, we could see the windrows were collecting the weed seeds. It was cleaner between the rows, so you could see the header was collecting the seeds.”

Once the new mechanical, vertical and more economical Seed Destructor was released, they made their move.

“When it went to the belt drive and vertical mill design, it became so simple. There are no right-angle gearboxes; it is just a shaft and a pulley. Each morning we greased a bearing on each side and that was it.”

The latest Harrington Seed Destructor can be fitted to later model John Deere, Case IH, New Holland and Claas harvesters. No permanent modifications are required.